Hernia repair is one of the most commonly performed surgical procedures worldwide, and the use of surgical mesh has significantly improved clinical outcomes over the past few decades. Hernia mesh provides durable reinforcement to weakened or damaged tissue, reducing recurrence rates and supporting long-term healing.

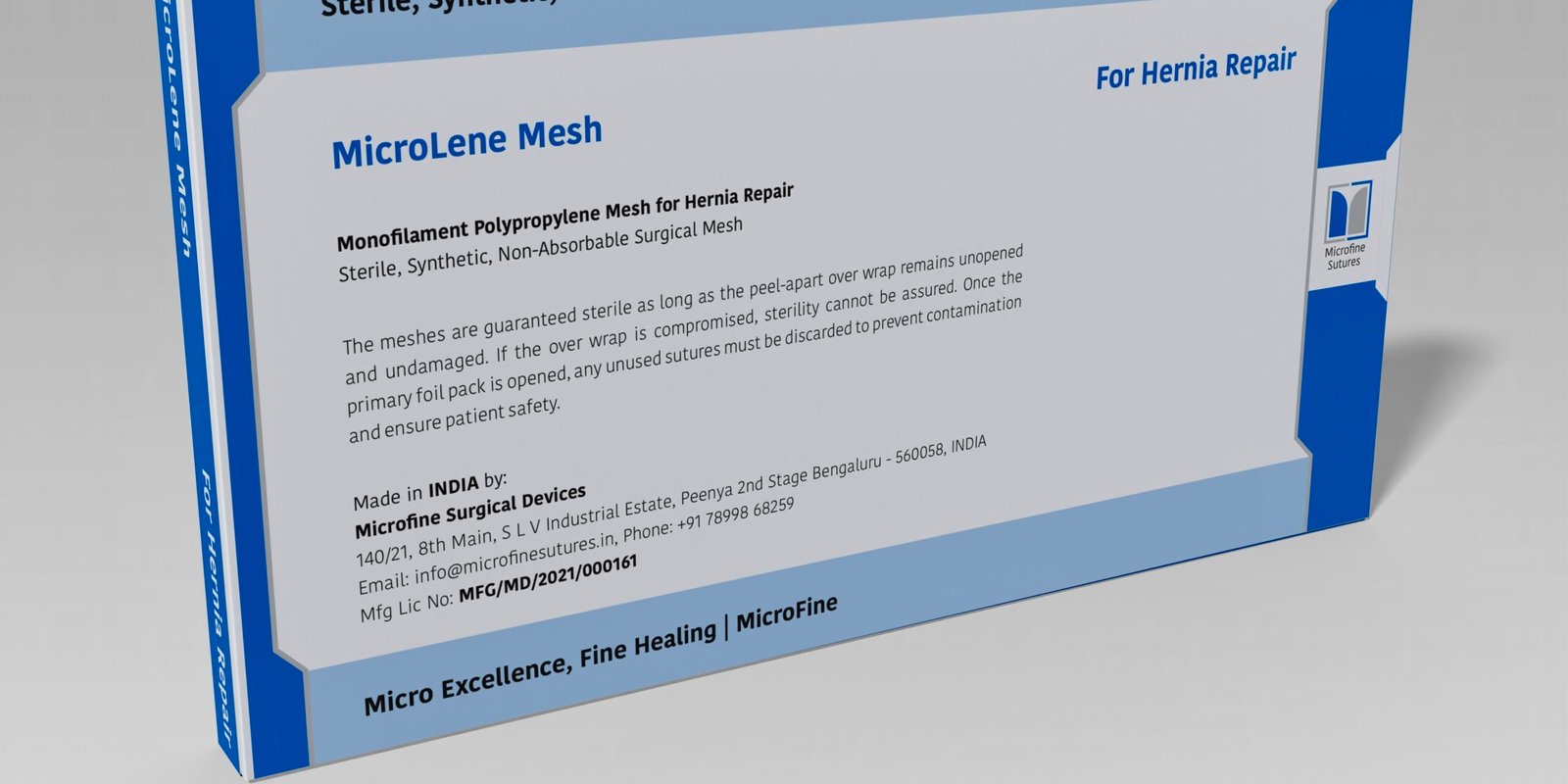

MicroLene Hernia Mesh has been developed to meet the evolving needs of modern hernia repair through precision manufacturing, material reliability, and consistent performance.

Role of Hernia Mesh in Modern Surgery

In traditional hernia repair techniques, sutures alone were often used to close the defect, which could place excessive tension on surrounding tissues. This tension increased the likelihood of recurrence and post-operative discomfort. The introduction of hernia mesh transformed surgical practice by enabling tension-free repair. Mesh acts as a scaffold that supports tissue regeneration and strengthens the abdominal wall, resulting in improved patient outcomes.

MicroLene Hernia Mesh is designed to provide optimal reinforcement while allowing natural tissue integration, making it an essential component in both open and laparoscopic hernia repair procedures.

Material Strength and Design Excellence

MicroLene Hernia Mesh is manufactured using high-quality polypropylene, a material widely accepted in surgical applications for its strength, flexibility, and biocompatibility. The mesh structure is engineered to provide balanced pore size and uniform filament construction, which supports tissue ingrowth and minimizes the risk of complications.

Its lightweight yet durable design ensures adequate mechanical support without compromising patient comfort. The mesh maintains dimensional stability while adapting to the anatomical contours of the repair site, enabling surgeons to achieve precise placement and reliable fixation.

Clinical Applications

MicroLene Hernia Mesh is suitable for a wide range of hernia repair procedures, including inguinal, ventral, umbilical, and incisional hernias. It can be effectively used in both open and minimally invasive surgical techniques. The mesh supports tension-free repair, helping to reduce recurrence rates and support faster recovery.

Surgeons value MicroLene Hernia Mesh for its ease of handling, minimal memory, and consistent performance during implantation.

Focus on Safety and Patient Outcomes

Patient safety remains a core priority in the design and manufacturing of MicroLene Hernia Mesh. The mesh is designed to promote rapid tissue integration while minimizing foreign body reaction. Its smooth construction supports reduced tissue irritation and contributes to improved post-operative comfort.

By reinforcing weakened tissue and supporting natural healing processes, MicroLene Hernia Mesh helps achieve stable and long-lasting repair outcomes.

Manufacturing and Global Supply Capability

MicroLene Hernia Mesh is manufactured under stringent quality control systems that comply with international medical device standards. From raw material sourcing to final sterilization and packaging, every stage of production is carefully monitored to ensure consistency, safety, and reliability.

In addition to manufacturing, MicroLene is a trusted exporter of hernia mesh, supplying products to hospitals, distributors, and healthcare systems across global markets. Strong production capacity and dependable logistics make MicroLene a reliable partner in surgical care worldwide.

Conclusion

MicroLene Hernia Mesh has become an essential component in modern hernia repair surgery by combining material strength, precision design, and proven clinical performance. With a strong commitment to quality manufacturing and global supply, MicroLene continues to support surgeons in delivering safe, effective, and durable hernia repair solutions.